Prime PC (Polycarbonate) Compounding

Prime PC (Polycarbonate) Compounding

E/E

Electric box, Smoke sensor enclosure

Bench mark grades eg. N190X,SE1X,SE100X,HS2000X,SE1GFN1,

SE1GFN2,SE1GFN3,PX9406,PX5622

Di-electrical strength, High heat, High impact, Dimension stability, Eco-FR

E/E

Electric box, Smoke sensor enclosure

Bench mark grades eg. N190X,SE1X,SE100X,HS2000X,SE1GFN1,

SE1GFN2,SE1GFN3,PX9406,PX5622

Di-electrical strength, High heat, High impact, Dimension stability, Eco-FR

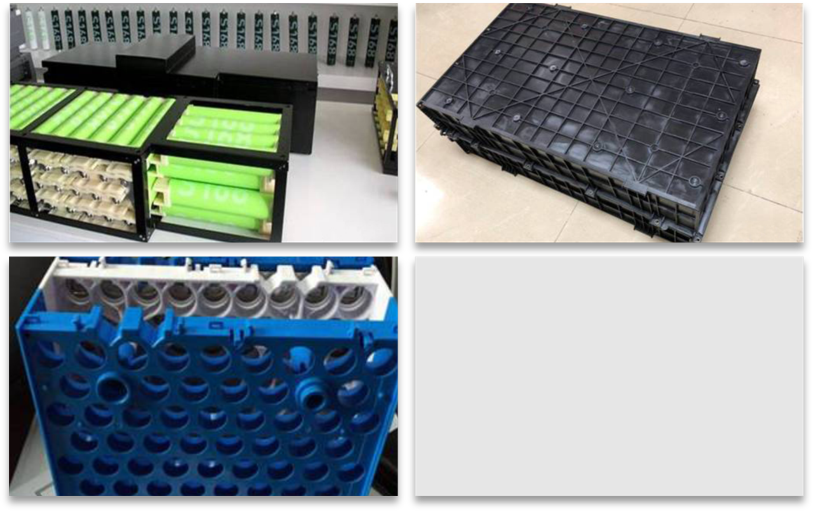

Light weight

Low warpage dimensionally stable

Non bromine and non chlorine flame retardant

Excellent electrolyte resistance performance

Easy to mold to fit for complex mold design

Light weight

Low warpage dimensionally stable

Non bromine and non chlorine flame retardant

Excellent electrolyte resistance performance

Easy to mold to fit for complex mold design

Water tank cover, water pump, ignition coil Coil frame, connector

Good dimensional stability and low shrinkage rate

Low water absorption, Low creep performance high tensile and modules at high temperature

Good balance between flame retardant, heat resistance, and toughness.

Water tank cover, water pump, ignition coil Coil frame, connector

Good dimensional stability and low shrinkage rate

Low water absorption, Low creep performance high tensile and modules at high temperature

Good balance between flame retardant, heat resistance, and toughness.

Exterior panels, wheel covers, mirror covers, cladding, rear panels, front fenders, intake pipes, fuse boxes and connectors

Low density, high strength, and high modulus;

Excellent high-temperature and low-temperature resistance

Excellent chemical resistance, good dimensional stability

Low mold shrinkage rate, and excellent surface quality

Exterior panels, wheel covers, mirror covers, cladding, rear panels, front fenders, intake pipes, fuse boxes and connectors

Low density, high strength, and high modulus;

Excellent high-temperature and low-temperature resistance

Excellent chemical resistance, good dimensional stability

Low mold shrinkage rate, and excellent surface quality

Water meter, valve, faucet

Bench Mark 731, GFN2, GFN3,GFN3V, ENG265

Low water absorption rate; Static pressure; Burst strength; Outdoor exposure; Torque strength; Compliant with NSF Std 61 requirements

Low creep; Approval of drinking water.

Parts can serve over 15 years;

Dimensional stability and hydrolysis stability;

90 ° C water contact; 1MPa; 500000 pressure cycles

Water meter, valve, faucet

Bench Mark 731, GFN2, GFN3,GFN3V, ENG265

Low water absorption rate; Static pressure; Burst strength; Outdoor exposure; Torque strength; Compliant with NSF Std 61 requirements

Low creep; Approval of drinking water.

Parts can serve over 15 years;

Dimensional stability and hydrolysis stability;

90 ° C water contact; 1MPa; 500000 pressure cycles

High strength, and transparent amorphous polymers

Glass transition temperature 185 ° C and above

Long term use temperature range -100 ° C and 150 ° C, even 200 ° C

Dimensional stability, with dimensional changes generally less than 0.1% in boiling water or 150 ° C air or steam environments

High strength, and transparent amorphous polymers

Glass transition temperature 185 ° C and above

Long term use temperature range -100 ° C and 150 ° C, even 200 ° C

Dimensional stability, with dimensional changes generally less than 0.1% in boiling water or 150 ° C air or steam environments

PES, PPSU, PSU, PEI products

Good impact High modules

Dimension stable

UV, GAMA RAY Sterilization

Pre-color, Master Batch, GF Services

PES, PPSU, PSU, PEI products

Good impact High modules

Dimension stable

UV, GAMA RAY Sterilization

Pre-color, Master Batch, GF Services

PP/PC/PPE/PPE/PEI/PES/PPSU

upon various temperature requirements

Good impact High modules

Dimension stable

EMI, ESD, Conductive , SR E3~6, E6~9, E9~11

Carbon Black, CF, IDP, CNT

PP/PC/PPE/PPE/PEI/PES/PPSU

upon various temperature requirements

Good impact High modules

Dimension stable

EMI, ESD, Conductive , SR E3~6, E6~9, E9~11

Carbon Black, CF, IDP, CNT

2010 © All Copyright By CMP Technology IPC: 粤ICP备2022039252号